|

|

You are here: Home > Products Products

| High Speed Engine Lathes - CL-22/CL-19 Series |

|

- High Rigidity Spindle

- Anti-Wear Slideway

- Low Noise, Rigged, Headstock

- Stiff Carriage

- Two Step Feed Tailstock

- Circular Brakes

- Robust Bed

- Optional Metri/Inch Gear Box

|

| High Speed Engine Lathes - CL-16 Series |

|

- Yang Engine Lathes

- High Rigidity Spindle

- Anti-Wear Slideway

- Low Noise, Rigged, Headstock

- Stiff Carriage

- Two Step Feed Tailstock

- Circular Brakes

- Robust Bed

- Optional Metri/Inch Gear Box

|

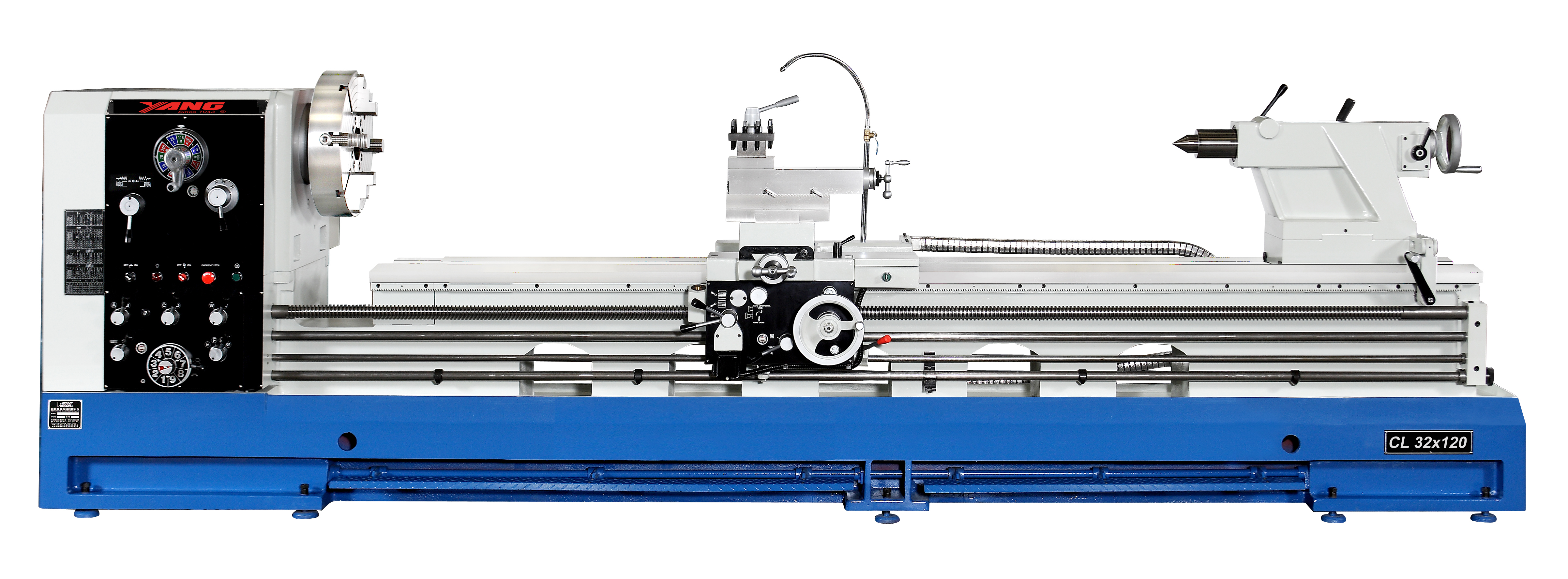

| High Speed Engine Lathes - CL-32" to 40" Series |

|

- Swing Over Bed: 32" - 40"

- Swing Over Cross Slide: 23" to 31.50"

- Swing Over Gap: 44" to 51"

- Taper of Spindle Bore: MT5

- Spindle Speed: 15~1000rpm (12 Steps)

- Click the link to see more specifications

|

| Gong Yang Milling Head - CNC Milling Head |

|

Product Name: CNC Milling Head

Model: U61/U71

Color: White

- Type: 20-35HP (For CNC heavy-duty cutting Machine)

- Designed for machine tools, including CNC heavy-duty double-column milling machines, dedicated machinery etc.

Model: U60/U70

- Type: 25HP inverter motor

- Designed for machine tools, including CNC heavy-duty double-column milling machines, dedicated machinery etc.

|

| CNC Lathes - Linear Way |

|

- Headstock triangular design with wide base

- Quick hydraulic tool turret with a quick indexing mechanism (optional on SL-12)

- Linear guideways provide high-speed rapid traverse rates.

- 45° slant bed design.

- Optimum chip outlet

|

| CNC Lathes - Heavy Duty Linear Way |

|

- High capacity cartridge spindle with four bearings.

- Premium heavy-duty linear guideways provides traverse rates of 1181 ipm.

- Quick hydraulic tool turret with tool-to-tool change time of 0.3 seconds.

- Ballscrews are anchored at both ends and ball nuts are pre-tensioned

|

| Vertical Machining Center - Linear Way |

|

Features:

- The structure parts are manufactured from Meehanite cast iron for maximum stability. All structural parts are tempered, stress relieved and combined with durable rib reinforcement to upgrade the machine rigidity and stability. This also assured lifetime accuracy of the machine.

- The major structures of the machine are analyzed and designed by the advanced Finite Element Analysis (FEM), featuring optional rigidity of structure, high speed machining resistance and low gravity center.

- The box way surfaces are hardened and precision ground. Slide-way surfaces are coated with wear-resistant media are low friction, coefficient, and precision scraped to assure accurate and smooth movement.

- The column is a Y shape construction for outstanding rigidity and stability.

- Precision linear-ways on 3 axes with extra smooth movement make the machine excellent for high speed and high precision machining.

- A laser unit is applied for inspection and calibrating the positioning accuracy. Inspection n made according to German VDI3441 standards. In addition, a ball bar tester is also applied for inspection static, dynamic circularity accuracy, servo and geometric error.

|

| Vertical Machining Center - Box Way |

|

Features:

- The structure parts are manufactured from Meehanite cast iron for maximum stability. All structural parts are tempered, stress relieved and combined with durable rib reinforcement to upgrade the machine rigidity and stability. This also assured lifetime accuracy of the machine.

- The major structures of the machine are analyzed and designed by the advanced Finite Element Analysis (FEM), featuring optional rigidity of structure, high speed machining resistance and low gravity center.

- The box way surfaces are hardened and precision ground. Slide-way surfaces are coated with wear-resistant media are low friction, coefficient, and precision scraped to assure accurate and smooth movement.

- The column is a Y shape construction for outstanding rigidity and stability.

- Precision linear-ways on 3 axes with extra smooth movement make the machine excellent for high speed and high precision machining.

- A laser unit is applied for inspection and calibrating the positioning accuracy. Inspection n made according to German VDI3441 standards. In addition, a ball bar tester is also applied for inspection static, dynamic circularity accuracy, servo and geometric error.

|

| Horizontal Machining Ctr - MH-500 |

|

- Extended spindle nose minimizes interference between headstock and workpiece while allowing a wide range of machining applications.

- Moving column and optimum structural rigidity result in superior accuracy and reliability.

- X, Y, and Z axes contain highly accurate, rugged linear guideways to assure rapid axis traverse while maintaining precision and accuracy.

- Single piece cast base and saddle promote durability and accuracy.

- Single piece cast base and saddle promote durability, accuracy, reduce backlash and guarantee accurate positioning and feeding.

- High pressure coolant system facilitates deep drilling and milling applications.

- Optional 4th axis available.

- Large capacity tool magazine accompanied with rapid tool change and random access selection, save time and offer higher productivity.

- Fully enclosed splash guard, double-sided slant linear guide covers and large volume coolant enable double screw chips augars to remove chips.

- Cooling system to extend tool life; telescopic covers and waterfall coolant designed to keep chips from remaining on the table or the augers.

- Splash guard device includes fully enclosed splash guard, chain type, screw type chip conveyors and chip cart.

|

| Horizontal Machining Ctr - MH-630 |

|

- Extended spindle nose minimizes interference between headstock and workpiece while allowing a wide range of machining applications.

- Moving column and optimum structural rigidity result in superior accuracy and reliability.

- X, Y, and Z axes contain highly accurate, rugged linear guideways to assure rapid axis traverse while maintaining precision and accuracy.

- Single piece cast base and saddle promote durability and accuracy.

- Single piece cast base and saddle promote durability, accuracy, reduce backlash and guarantee accurate positioning and Feeding.

- High pressure coolant system facilitates deep drilling and milling applications.

- Optional 4th axis available.

- Large capacity tool magazine accompanied with rapid tool change and random access selection, save time and offer higher productivity.

- Fully enclosed splash guard, double-sided slant linear guide covers and large volume coolant enable double screw chips augars to remove chips.

- Cooling system to extend tool life; telescopic covers and waterfall coolant designed to keep chips from remaining on the table or the augers.

- Splash guard device includes fully enclosed splash guard, chain type, screw type chip conveyors and chip cart.

|

| Horizontal Machining Ctr - MH-800 |

|

- Extended spindle nose minimizes interference between headstock and workpiece while allowing a wide range of machining applications.

- Moving column and optimum structural rigidity result in superior accuracy and reliability.

- X, Y, and Z axes contain highly accurate, rugged linear guideways to assure rapid axis traverse while maintaining precision and accuracy.

- Single piece cast base and saddle promote durability and accuracy.

- Single piece cast base and saddle promote durability, accuracy, reduce backlash and guarantee accurate positioning and feeding.

- High pressure coolant system facilitates deep drilling and milling applications.

- Optional 4th axis available.

- Large capacity tool magazine accompanied with rapid tool change and random access selection, save time and offer higher productivity.

- Fully enclosed splash guard, double-sided slant linear guide covers and large volume coolant enable double screw chips augars to remove chips.

- Cooling system to extend tool life; telescopic covers and waterfall coolant designed to keep chips from remaining on the table or the augers.

- Splash guard device includes fully enclosed splash guard, chain type, screw type chip conveyors and chip cart.

|

|

![YangMachines [logo]](../images/logo.jpg)

![YangMachines [logo]](../images/logo.jpg)